Specialty Lab Exhaust Assemblies

Exhaust ventilation is the primary means of preventing exposure to hazardous substances in research laboratories and other industrial workplaces. The appropriate type of exhaust system will depend on the processes and materials used in a facility’s operation.

These lab exhaust systems serve a critical, life-safety role, and must therefore be carefully designed to provide sufficient capacity, air velocity, and pressure to reliably collect and transport all hazardous airborne substances (e.g. fumes, flammable vapors, airborne pathogens, radioactive particulate, etc.) from the room. They must also be designed to prevent re-entrainment and the return of such contaminants back into the building environment.

Sander Mechanical offers a variety of technologically advanced exhaust systems (from PennBarry, Strobic Air, and others) that work in concert with laboratory fume hoods and other enclosures. Our laboratory and industrial process fume exhaust systems include both induction and non-induction solutions, to provide the right balance of flows, energy costs, and noise levels.

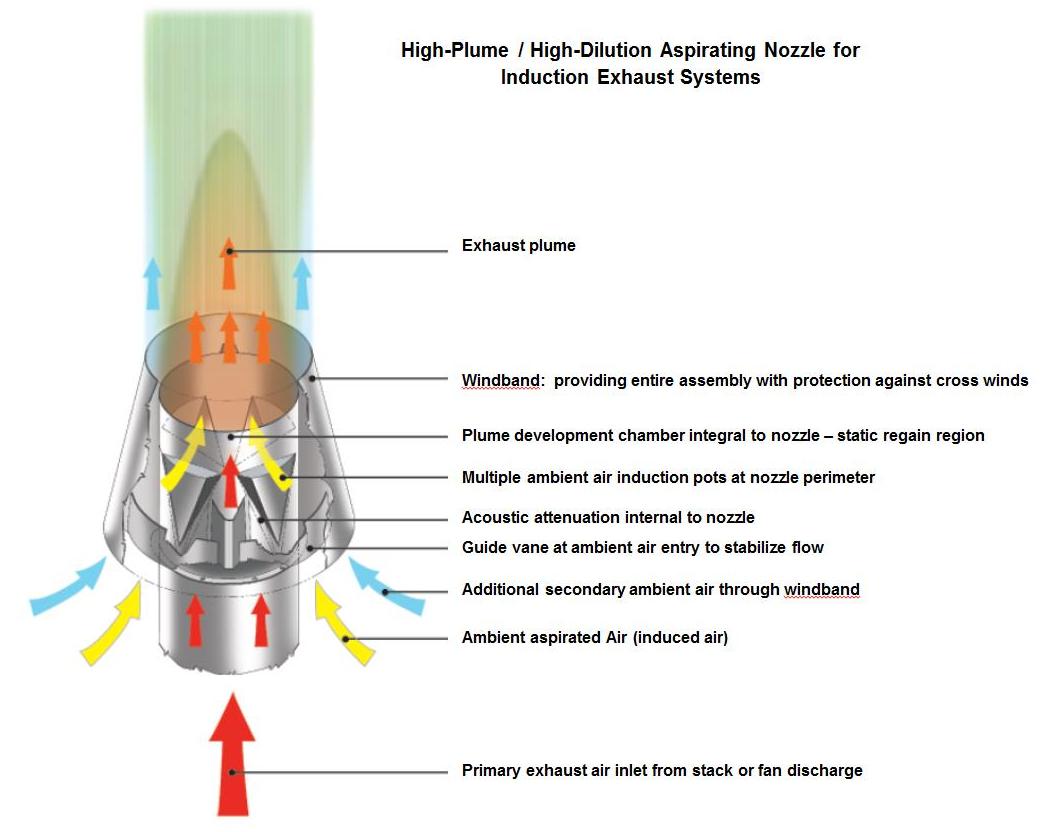

For critical applications, high-plume, induction exhaust systems will discharge building effluent and contaminants up and away from the facility by vertically exhausting the fumes up into the atmospheric jet stream using high fan output velocity. These systems rely on an efficient mixed flow fan coupled to a unique aspirating induction nozzle to sufficiently dilute and expel the contaminated airstream. The system effectively induces additional air flow from the ambient to increase the mass flow of the primary exhaust effluent. As a result, these “HY-PLUME” induction systems perform well in true dynamic ambient conditions, where crosswinds exist.

The available combinations of fans and nozzles provide a reliable, cost-effective alternative to conventional centrifugal exhaust fans, which are usually associated with tall, unsightly stacks.

Benefits of High Plume Induction Exhaust Assemblies over Traditional Utility Sets

- Purpose-designed for lab and life safety applications;

- Designed to meet criteria of ANSI/AIHA Z9.5 (2012) standard for Laboratory Ventilation (10 foot minimum discharge height above roof line and 3000 FPM minimum discharge velocity);

- Discharges building effluent higher into the atmospheric jet stream;

- Prevents re-entrainment of exhaust air into building fresh air intake;

- Eliminates potential corrosive/chemical interaction between effluent and nearby building components, such as the roofing system;

- Plume performance minimally impacted in dynamic ambient conditions (i.e. crosswind)

- Does not require additional guy wire supports or vibration isolation

- Direct drive fan eliminates drive losses and maintenance inherent in belt-drive systems;

- Lightweight, modular construction;

- Low profile design;

- Maintenance-free operation;

- Low noise levels;

- Lower operating costs.

Over four decades, Sander Mechanical has been assisting laboratory research, universities, public health, government, chemical, pharmaceutical, industrial and other process facilities to custom design, install, and maintain specialty ventilation and exhaust systems, with an eye towards achieving each of their environmental, life safety, and energy efficiency goals.

Contact us today to speak with one of our laboratory design specialists.